The 9 Secrets of BelGioioso

The milk that is gathered daily is delivered directly to a nearby plant that is dedicated to its own cheese type. There are several steps in the cheesemaking process that are essential to producing the best flavor, texture and aroma. Each of these steps requires the skill and attention of a devoted cheesemaker.

Home Grown Starter Cultures – Roadmap to Flavor

Starter culture is what helps to develop the individual flavors of the cheese. Many cheese producers purchase their starter cultures from a supplier. At BelGioioso, we grow our own starter cultures on a daily basis. Starter culture is made from the whey of a previous batch of cheese. It is added to the milk at a specific temperature and begins the ripening process. Each cheese has its own unique starter culture. It is a roadmap, of sorts, that tells the milk what type of cheese it will become. By using our own starter culture, the flavor and consistency of our cheese is handed down from batch to batch and generation to generation. This gives every BelGioioso cheese a flavor that cannot be matched by anyone else.

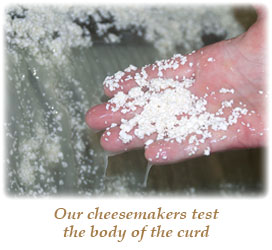

Curd Formation – Roadmap to Texture

Next, rennet is added to the fresh milk to begin the transformation from milk to cheese (the curdling process). For this reason BelGioioso is diligent about every step that makes our curd unique: setting, resting, cutting, agitation, cooking, stirring and pressing. It is a hands-on process that requires the cheesemaker to use all his senses to determine the precise time for each step. BelGioioso believes that curd formation is a little like alchemy, part science and part artistry.

Natural Salt Brining

The cheese’s salting is another crucial step that contributes to a large extent the quality and the development of the cheese. BelGioioso takes extra steps using the traditional method of natural salt brining its cheese. Brining is a process similar to marinating. The young cheese is soaked in a salt water solution for a specific period of time. During the brining process, the salt is absorbed by the cheese. The salt in the solution draws moisture out of the cheese and helps in the formation of the rind. Strict attention is paid during this time in order to control the acidity, temperature and salt concentration. A balanced salt level is essential to develop the proper flavor of the cheese.

Brining is a hands-on process. Each wheel must be turned every day, by hand, to ensure the consistent absorption and distribution of the salt on all sides. This is a very laborious and lengthy process but is best for the production of quality cheese.

Our traditional brining method creates a solid cheese body, uniform color and cheese with the right amount of salt and a clean finish. Most of our competitors add salt directly to the curd. This less costly shortcut does not provide an even distribution of the salt and the whey becomes trapped and taints the flavor. The result is a cheese with mechanical openings and an unclean aftertaste.

Air Drying Room

BelGioioso master cheesemakers uphold the tradition of air drying cheese to naturally remove moisture. In our specialized climate controlled caves, our cheesemakers carefully inspect and hand-turn each wheel to ensure proper drying, rind formation, uniform distribution of salt and development of flavor. This care and craft guarantees that our Parmesan and American Grana® develop a beautiful golden rind, pale straw colored body and sweet, nutty flavor.

The Aging Room

Aging is a slow, tedious process and requires the cheesemaker to wait patiently to see the results of his labor. Once again, traditional methods are the best way to fulfill this task. During the aging process, fats and proteins undergo a transformation. The cheese begins to assume its characteristic flavor. The aging cheese also changes color and becomes a deeper straw color and the flavor is further enhanced. It took many years to establish the optimal environment in which the cheese would age and evolve. BelGioioso aging rooms have been in use for decades and have been allowed to develop an outstanding microbiological environment that gives the cheese its specific characteristics. Temperature and moisture are monitored constantly. The right environment, however, is only part of the equation.

While aging, the cheese is looked after carefully, hand turned often and cleaned regularly. Some varieties are hand washed with water and salt during this time. The experience of the BelGioioso cheesemakers allows them to know exactly when a cheese is ready to be cut and eaten.

Many competitors skip steps in order to save time and money. They add more enzymes to develop flavor and cook the curd longer and hotter to reduce the curing time. Overcooking the curd can burn the natural sugars in the milk and can result in a burnt aftertaste. Their cheese does not have a rind and has a brownish colored body.

Cheese is a living product, the result of many variables; some completely natural, others managed by humans. It is an evolution that requires time, patience and constant attention to achieve the right amount of aging. BelGioioso knows the "story" behind each wheel of cheese that it crafts. You've heard that happy cows make great cheese? Well, at BelGioioso we know that it isn't the happy cows that make great cheese, it's our happy cheesemakers!

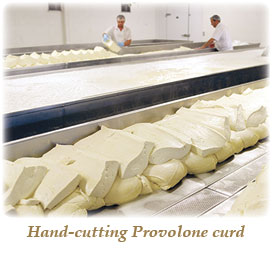

Artisan Production Methods